DI Frame and Grates

DI Frame and Grates Specification

- Shape

- Rectangular, Square

- Height

- Varies as per design, typically 60mm-100mm

- Length

- Varies as per specification

- Product Type

- DI Frame and Grates

- Material

- Ductile Iron (DI)

- Application

- Drainage Systems, Roadways, Industrial Areas, Sidewalks

- Surface Treatment

- Black Painted, Anti-Corrosive Coating

- Size

- Standard and Custom Sizes Available

DI Frame and Grates Trade Information

- Minimum Order Quantity

- 10 Tons

- FOB Port

- Kolkata

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 200 Tons Per Week

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Pallets

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001-2015 Govt Certified Export House

About DI Frame and Grates

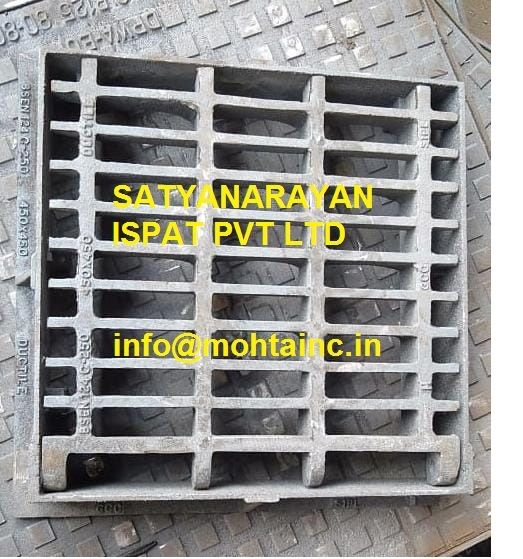

DUCTILE IRON or DUCTILE CAST IRON 500/7 Grade

DUCTILE IRON FRAME & GRATE

DUCTILE IRON FRAME & GRATING

DUCTILE IRON MANHOLE GRATING

DI GRATINGS & FRAME

BSEN124 C250 / D400 Grade

300x300 mm or 12x12 inch or 1x1 foot - DI Frame & Grate - BSEN124 C250/D400 Load - Ductile Iron

450x450 mm or 18x18 inch or 1.5x1.5 foot - DI Frame & Grate - BSEN124 C250/D400 Load - Ductile Iron

600x600 mm or 24x24 inch or 2x2 foot - DI Frame & Grate - BSEN124 C250/400 Load - Ductile Iron

Robust Construction and Reliable Performance

Made from high-quality ductile iron, our frames and grates provide exceptional strength and reliability. Their anti-corrosive surface treatments and smooth finish ensure long-lasting service in the most challenging environments, such as industrial areas and roadways. Advanced locking mechanisms help prevent unauthorized access and theft while supporting functionality and safety.

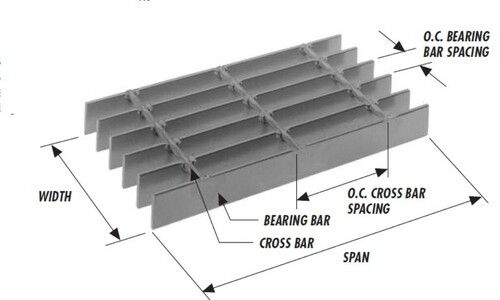

Customizable Solutions for Diverse Applications

Available in rectangular and square shapes, with both standard and custom sizing, our DI grates accommodate a wide array of drainage and surface requirements. The choice between solid top or perforated lids provides versatility for various water flow and load scenarios. Each unit is designed to ensure efficient surface drainage and easy installation through both surface and flush mounting options.

FAQs of DI Frame and Grates:

Q: How is the load bearing capacity of DI Frame and Grates determined according to standards?

A: The load bearing capacity is tested and certified up to Class D400, meeting EN124 and IS 12592 standards, ensuring suitability for heavy-duty environments like industrial areas and busy roadways.Q: What types of finishes and corrosion protection do these frames and grates offer?

A: They feature a smooth, uniform finish with black painted and anti-corrosive coatings, effectively guarding against rust and prolonging their service life, even when exposed to harsh weather or chemicals.Q: When should solid top or perforated lids be selected for installation?

A: Solid top lids are preferred when solid coverage and strength are required, while perforated lids allow water flow and are ideal for drainage applications needing effective surface runoff management.Q: Where can DI Frame and Grates be installed?

A: These units are suitable for a wide range of settings, including drainage systems, sidewalks, industrial parks, and roadways. Depending on project needs, they support both surface mount and flush mount installations.Q: What is the process for customizing the size and shape of the grates?

A: Customization requests can be accommodated based on design specifications, with options available for both rectangular and square shapes, as well as varying heights and lengths to fit project requirements.Q: How are the DI frames and grates protected against theft and unauthorized access?

A: Each product integrates a bolted locking mechanism, delivering robust anti-theft protection and ensuring the grates remain securely in place.Q: What are the main benefits of installing DI Frame and Grates from this manufacturer?

A: Benefits include superior load-bearing performance, long service life (over 15 years under normal conditions), rust and corrosion resistance, customizable design, adherence to internationally recognized standards, and reliable anti-theft mechanisms.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gratings Category

DI Channel Grating

Price 1200 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Size : Customized

Color : Black

Shape : Rectangle

Length : 500 to 750 mm Millimeter (mm)

Ductile Iron Trench Grate

Price 1200.00 USD ($) / Ton

Minimum Order Quantity : 20 Tons

Size : 100 to 1000 mm

Color : Black / Yellow

Shape : Rectangle

Length : 300 to 1000 mm Millimeter (mm)

GI Grating

Price 85 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Size : 100 to 1000mm

Color : Black / Silver

Shape : Square

Length : 300 to 1000 mm Millimeter (mm)

Ductile Iron Gratings

Price 1200.00 USD ($) / Ton

Minimum Order Quantity : 10 Tons

Size : 5 to 14 inches

Color : black

Shape : Rectangle

Length : 20 to 30 Inch (in)

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese